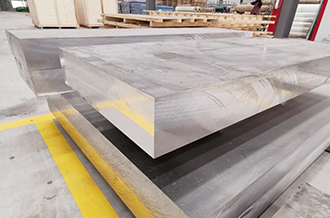

2219 aluminum alloy is a famous high-strength and heat-resistant alloy. This copper containing alloy has extremely high toughness and excellent stress corrosion resistance after treatment, making it an excellent metal for the manufacturing of supersonic aircraft components and high-temperature structural applications.

Chalco is one of the well-known producers and suppliers of 2219 aluminum plates. Chalco 2219 aluminum plate has good fracture toughness, stress corrosion resistance, structural strength, and mechanical properties. It is a designated supplier for the well-known airlines such as Boeing, Collins Aerospace, and Airbus.

Chalco 2219 T851 aluminum plate stock sizes

|

Description

|

Thickness/inch

|

Thickness/mm

|

Width*length(mm)

|

|

AMS-QQ-A250/30 0.500 2219 T851 Aluminum plate

|

0.500

|

12

|

1000*2000

|

|

AMS-QQ-A250/30 0.500 2219 T851 Aluminum plate

|

0.500

|

12

|

1200*2400

|

|

AMS-QQ-A250/30 0.600 2219 T851 Aluminum plate

|

0.600

|

15

|

1500*3000

|

|

AMS-QQ-A250/30 1.000 2219 T851 Aluminum plate

|

1.000

|

25

|

1500*3000

|

|

AMS-QQ-A250/30 1.375 2219 T851 Aluminum plate

|

1.375

|

35

|

1000*2000

|

|

AMS-QQ-A250/30 1.375 2219 T851 Aluminum plate

|

1.375

|

35

|

1200*2400

|

|

AMS-QQ-A250/30 1.750 2219 T851 Aluminum plate

|

1.750

|

45

|

1500*3000

|

|

AMS-QQ-A250/30 1.750 2219 T851 Aluminum plate

|

1.750

|

45

|

1000*2000

|

|

AMS-QQ-A250/30 1.750 2219 T851 Aluminum plate

|

1.750

|

45

|

1200*2400

|

|

AMS-QQ-A250/30 2.375 2219 T851 Aluminum plate

|

2.375

|

60

|

1000*2000

|

|

AMS-QQ-A250/30 2.375 2219 T851 Aluminum plate

|

2.375

|

60

|

1200*2400

|

|

AMS-QQ-A250/30 3.000 2219 T851 Aluminum plate

|

3.000

|

75

|

1000*2000

|

|

AMS-QQ-A250/30 3.000 2219 T851 Aluminum plate

|

3.000

|

75

|

1200*2400

|

|

AMS-QQ-A250/30 3.500 2219 T851 Aluminum plate

|

3.500

|

90

|

1000*2000

|

|

AMS-QQ-A250/30 3.500 2219 T851 Aluminum plate

|

3.500

|

90

|

1200*2400

|

|

AMS-QQ-A250/30 4.000 2219 T851 Aluminum plate

|

4.000

|

100

|

1000*2000

|

|

AMS-QQ-A250/30 4.000 2219 T851 Aluminum plate

|

4.000

|

100

|

1200*2400

|

Mechanical properties of 2219 T851 aluminum plate

|

Material

|

Thickness

|

Tensile Strength ksi

|

Yield Strength ksi

|

Elongation in 2" (%)

|

|

Alloy 2219-T851 (QQ-A-250/30)

|

0.250"-2.00"

|

62

|

46

|

7-8

|

Chemical composition pf 2219 T851 aluminum plate

|

Element

|

Composition % (AMS 4094 2219-T851)

|

|

Al

|

91.5-93.8

|

|

Cu

|

5.8-6.8

|

|

Mn

|

0.2-0.4

|

|

Zr

|

0.1-0.25

|

|

Fe

|

Max. 0.3

|

|

Si

|

Max. 0.2

|

|

V

|

0.05-0.15

|

|

Ti

|

0.02-0.1

|

|

Zn

|

Max. 0.1

|

|

Mg

|

Max. 0.02

|

Thermal properties of 2219 T851 aluminum plate

|

Thermal properties

|

Metric

|

English

|

Comments

|

|

CTE, linear 68°F

|

22.3 µm/m-°C

|

12.4 µin/in-°F

|

AA; Typical; Average over 68-212°F range.

|

|

CTE, linear 250°C

|

24.1 µm/m-°C

|

13.4 µin/in-°F

|

Estimated from trends in similar Al alloys. 20-300°C.

|

|

Specific Heat Capacity

|

0.864 J/g-°C

|

0.207 BTU/lb-°F

|

|

|

Thermal Conductivity

|

120 W/m-K

|

833 BTU-in/hr-ft²-°F

|

|

|

Melting Point

|

543 - 643 °C

|

1010 - 1190 °F

|

AA; Typical range based on typical composition for wrought products 1/4 inch thickness or greater. Eutectic melting is not eliminated by homogenization.

|

|

Solidus

|

543 °C

|

1010 °F

|

AA; Typical

|

|

Liquidus

|

643 °C

|

1190 °F

|

AA; Typical

|

Application of 2219 T851 aluminum plate

T851 is a heat treated temper of 2219 aluminum plate, which has undergone solution heat treatment and artificial aging. In the T851 temper, the strength and hardness of 2219 aluminum plate are improved, the corrosion resistance is enhanced, good toughness and fracture toughness are maintained, thermal stability is enhanced. It has a wide range of applications in the aerospace field.

-

Supersonic aircraft skin, effectively reducing the weight of supersonic aircraft;

-

Aerospace fuel tanks;

-

High strength parts and welded structures;

-

Spacecraft components, materials provide sufficient structural strength to adapt to various extreme environments and mechanical challenges in space.

-

Space booster structural components, materials can withstand extreme pressure during space launch and operation

-

Rocket engine casing, materials can withstand the challenges of high temperature and high pressure environments in rocket engines.

Related products