Aluminum Checker Plate Sheet

Aluminum Checker sheets are created by using a rolling machine to press patterns onto the surface of aluminum plates. The raised patterns commonly include 1 bar, 2 bars, 3 bars, and 5 bars. These aluminum tread plate find extensive use in construction, vehicles, ships, and various applications requiring non-slip flooring or decorative finishes.

Chalco hot selling aluminum checkered plate products

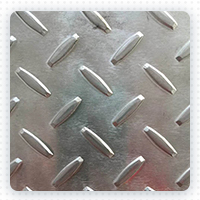

1 bar aluminum checker plate

A "1-bar" aluminum checker plate, also known as a "Willow leaf " aluminum checker plate due to its distinct design, is a common style of non-slip aluminum sheet. It provides excellent slip resistance and is mainly used for carriage, platform, cold storage floor, workshop floor, and elevator flooring applications.

Alloys: 1050, 1060, 1070, 3003, 5052, 5754, 3105, 6061, 6063, 6082

Rib height: 0.8-1.3mm

Base plate thickness: 0.8-8mm

Width: 100-1850mm

Length: 500-16000mm

Standard sizes: 1250x2500mm (48”x96”), 1219x2440mm, 1524x3048mm (60”x120”), up to 2000mm wide, customizable for special specifications.

2 bar aluminum checker plate

The surface of the 2 bar aluminum checker plate exhibits a design resembling two elongated leaves, setting it apart from regular smooth aluminum materials, providing the aluminum sheet with a distinct appearance and texture. It is commonly used in wall cladding, ceilings, furniture, and other decorative applications, offering a unique visual effect to spaces.

Alloys: 1050, 1060, 1070, 3003, 5052, 5754, 3105, 6061, 6063, 6082

Rib height: 0.8-1.3mm

Base plate thickness: 0.8-8mm

Width: 100-1850mm

Length: 500-16000mm

Standard sizes: 1250x2500mm (48”x96”), 1219x2440mm, 1524x3048mm (60”x120”), up to 2000mm wide, customizable for special specifications.

3 bar aluminum checker plate

The 3-bar aluminum checker plate features a single-side pattern with three raised diamond-shaped or linear bars, providing excellent anti-slip properties. Consequently, it is commonly employed in loading ramps, dock flooring, stair treads, and even as floor plates for automobiles, trucks, ambulances, and fire engines to ensure anti-skid capabilities.

Alloys: 1050, 1060, 1070, 3003, 5052, 5754, 3105, 6061, 6063, 6082

Rib height: 0.8-1.3mm

Base plate thickness: 0.8-8mm

Width: 100-1850mm

Length: 500-16000mm

Standard sizes: 1250x2500mm (48”x96”), 1219x2440mm, 1524x3048mm (60”x120”), up to 2000mm wide, customizable for special specifications.

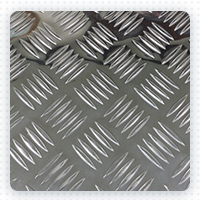

5 bar aluminum checker plate

The 5-bar aluminum checker plate has a single-side pattern featuring five raised diamond-shaped or linear bars. The added texture reduces the risk of sliding, offering superior anti-slip effects among various checker plate. It is widely used in cold storage installation, automobiles, buses, high-speed trains, decorative wall panels, cabinets, ceilings, and other touch surfaces due to its excellent anti-skid properties.

Alloys: 1050, 1060, 1070, 3003, 5052, 5754, 3105, 6061, 6063, 6082

Rib height: 0.8-1.3mm

Base plate thickness: 0.8-8mm

Width: 100-1850mm

Length: 500-16000mm

Standard sizes: 1250x2500mm (48”x96”), 1219x2440mm, 1524x3048mm (60”x120”), up to 2000mm wide, customizable for special specifications.

Aluminum diamond plate

The pattern on the Aluminum Diamond Plate is like a compass and is also used as a non-slip aluminum plate. Aluminum diamond plate can be used for anti-skid surfaces in carriages, service platforms, cold storage floors, workshop floors, and elevator car anti-skid surfaces.

Alloys: 1050, 1060, 1070, 3003, 5052, 5754, 3105, 6061, 6063, 6082

Rib height: 0.8-1.3mm

Base plate thickness: 0.8-8mm

Width: 100-1850mm

Length: 500-16000mm

Standard sizes: 1250x2500mm (48”x96”), 1219x2440mm, 1524x3048mm (60”x120”), up to 2000mm wide, customizable for special specifications.

Characteristics of Different Alloy aluminum checker plate

aluminum checker plate exhibit various characteristics based on different alloy compositions. They are categorized into several types: general aluminum alloy checker plate, aluminum-manganese alloy checker plate, aluminum-magnesium alloy checker plate, and aluminum-magnesium-silicon alloy checker plate. These distinct alloys offer diverse properties suitable for a wide range of applications.

Pure Aluminum Checker Plate

The 1060 aluminum-based checker plate is suitable for common environments and is cost-effective. It is commonly used in applications like cold storage, flooring, and external packaging.

Aluminum-Manganese Alloy Checker Plate

Derived mainly from 3003, this checker plate, also known as rust-resistant aluminum, offers slightly higher strength than standard aluminum checker plates. It possesses some anti-rust properties but doesn't match the hardness and corrosion resistance of 5000 series checker plates. It is suitable for less demanding rust prevention requirements, such as truck models and cold storage flooring.

Aluminum-Magnesium Alloy Checker Plate

Processed from 5052, 5083, and other 5000 series aluminum plates, this checker plate provides excellent corrosion resistance, hardness, and anti-rust performance. Typically used in specialized environments like ships and carriage lamps in humid conditions, it possesses high hardness and a certain load-bearing capacity.

Aluminum-Magnesium-Silicon Alloy Checker Plate

Derived from 6061 and 6082 aluminum plates, this aluminum alloy checker plate offers better corrosion resistance, increased strength, strong weldability, and finds applications in the chemical industry, as well as for decoration in ships and port facilities.

FAQs for Purchasing Aluminum Checker Plate

Q: How to choose the right thickness?

A: The choice of thickness is closely related to the intended application. In flooring applications, the support structure affects the selection of the Aluminum checker plate thickness. Generally, the stronger the support, the thinner the required Aluminum checker plate can be.

Q: How to choose different patterns?

A: For wall decoration, it's recommended to use one bar, two bars, three bars, or compass rose patterns, which enhance the aesthetic appeal. For slip-resistant flooring, the 5 bar aluminum checker plate is more suitable due to its denser pattern, providing superior slip resistance.

Q: How to select different surface-treated patterns?

A: Different surface treatments of aluminum checker plate offer various applications. The mill finish is typically used for slip-resistant flooring, providing good anti-slip properties; the bright finish suits manufacturing toolboxes and exhibits a glossy appearance. The anodized finish is primarily for decorative purposes, providing additional decorative characteristics, often used in decorative materials.

Q: What's the difference between hot-rolled and cold-rolled aluminum checker plate?

A: Hot-rolled aluminum checker plate is generally superior to the cold-rolled version, as hot-rolled material exhibits a more uniform microstructure with fewer defects and cracks. Cold-rolled material may have numerous micro-defects and cracks, prone to cracking when bent. All our products undergo hot rolling to ensure the highest product quality.

Q: What precautions should be taken during aluminum checker plate transportation?

A: During transportation of aluminum checker plates, proper packaging such as plastic film or foam padding is recommended to prevent external impacts or compression. It's best to opt for enclosed vehicle compartments or cargo holds to prevent sliding or shaking of the plates.