Honeycomb Aluminum Panel

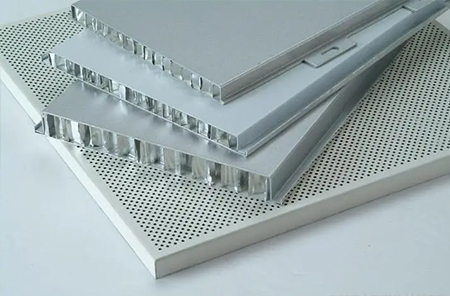

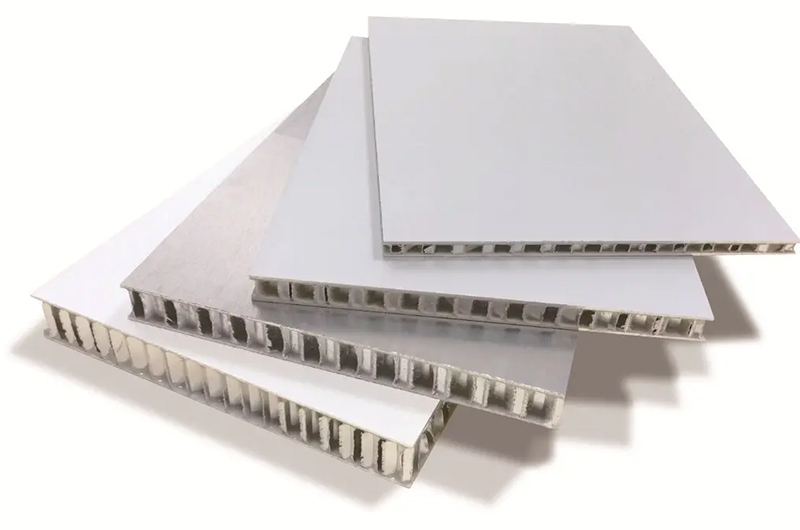

Aluminum honeycomb panel is a sandwich-structured composite material consisting of an aluminum honeycomb core and two layers of panels. It features high hardness, ease of processing, smooth surface, and heat and corrosion resistance.

Widely used in interior and exterior decoration of buildings, as well as in the decorative and partitioning aspects of ships, yachts, transportation, trains, railways, and the shipbuilding industry.

Specifications of aluminum honeycomb panel

Standard size: 1200x2500mm, 1500x3500mm; 48 inch x 96 inch, 48 inch x 120 inch,48 inch x 144 inch

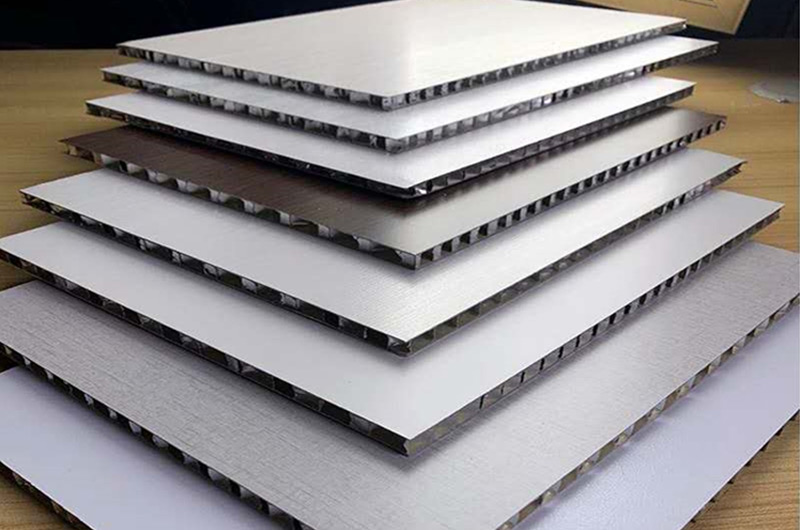

Standard thickness: 6mm, 10mm, 15mm, 20mm 25mm; 0.125 inch, 1.0 inch, 0.75 inch, 0.625 inch, 0.5 inch, 0.375 inch, 0.25 inch

Biggest size: 1600x 12000mm, 2500x6000mm

From minimum to maximum thickness: 3mm-500mm

Types of aluminum honeycomb panels

Chalco Aluminum offers two types of honeycomb aluminum panels: general-purpose and fire-resistant, with customization options available.

General-purpose honeycomb aluminum panel

Surface layer: AA3000, AA5000

Panel thickness: 0.5mm, 0.7mm, 0.8mm, 1mm, 3mm, Other thicknesses can be customized according to needs.

Surface treatment: VDF coating, paint, wood grain, stone grain, anodizing, mirror, etc.

Honeycomb core: AA 3003 H18, AA 5052 H18

Honeycomb core specifications: Honeycomb core with a diameter of 9.5mm and side length of 6mm, custom sizes are also available upon request.

Adhesive: Standard adhesive, high-temperature adhesive

Certification: ASTM E 84, Non-combustibility test EN ISO1182, IMO MED Module B+D, certified by LR

Aluminum honeycomb fireproof panel

Surface layer: Fireproof material

Surface treatment: Wood grain, stone grain, coating, solid

Honeycomb core: AA 3003 H18, AA 5052 H18

Honeycomb core specifications: Honeycomb core with a diameter of 9.5mm, side length of 6mm, and custom sizes available upon request.

Adhesive: Standard adhesive, high-temperature adhesive

Certification: ASTM E 84, Non-combustibility test EN ISO1182, IMO MED Module B+D, certified by LR

Characteristics of aluminum honeycomb panels

Characteristics of universal honeycomb aluminum plate

- Aluminum honeycomb panels feature a hexagonal biomimetic structure in their honeycomb core, providing a high level of smoothness.

- Aluminum honeycomb panels can be customized according to customer requirements, including processing into curved or irregular shapes.

- Various colors can be achieved on aluminum honeycomb panels through processes such as roller coating, spray coating, or anodizing, offering a wide range of color choices for an elegant decorative effect.

- Aluminum itself possesses excellent rust resistance and corrosion resistance, ensuring a long lifespan and environmental friendliness through recyclability.

Characteristics of universal honeycomb aluminum plate

- Aluminum honeycomb panels feature a hexagonal biomimetic structure in their honeycomb core, providing a high level of smoothness.

- Aluminum honeycomb panels are flame-retardant materials, achieving A2 fire resistance level.

- The individual closed cells in the honeycomb core effectively block sound waves and heat, significantly reducing the sound propagation and thermal conductivity coefficients of the panels, resulting in excellent soundproofing, thermal insulation, and heat preservation effects.

- Aluminum honeycomb panels are lightweight materials with a robust and sturdy structure due to their hexagonal biomimetic honeycomb core, offering high strength.

Application of aluminum honeycomb panels

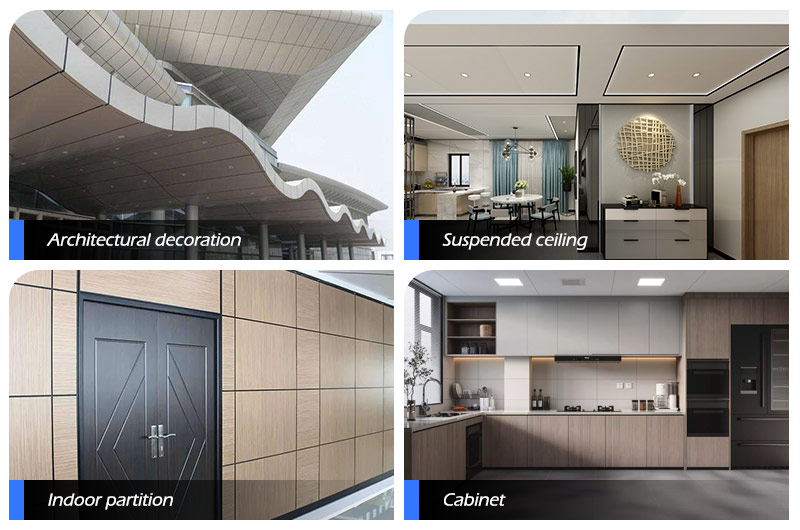

Interior and exterior building applications

Honeycomb aluminum panels find applications in the interior and exterior decoration of various structures, including residential buildings, offices, and commercial establishments.

They are used in hospitals, clinics, schools, educational institutions, industrial buildings, cultural and sports facilities, hotels, and more.

Marine industry

In the shipbuilding industry, fire-resistant aluminum honeycomb panels are incorporated into the design of ships, large yachts, patrol boats, and even offshore platforms to achieve higher efficiency and operational effectiveness.

Transportation

Aluminum honeycomb panels are suitable for applications in transportation, such as carriages and electric ramps. By using lightweight aluminum honeycomb panels, the overall weight of the vehicle can be reduced, increasing its load capacity.

Petrochemical industry

In the petrochemical field, large oil tanks primarily utilize aluminum honeycomb panels as internal floating roofs.

The use of honeycomb panels maximizes the tank's capacity by ensuring complete contact with the stored medium.

Trains, aircraft, and rail transport

Aluminum honeycomb panels can be manufactured into complex shapes, meeting requirements for performance, size tolerances, and aesthetic quality.

They are utilized in train carriages for partitions, doors, ceilings, and luggage rack liners. In aircraft, honeycomb panels are employed for cabin partitions, doors, and ceilings.

Raised floors

Aluminum honeycomb panels are suitable for constructing raised floors, creating hidden spaces between two floors in buildings for pathways and MEP services.

Furniture

Due to its ease of processing, a wide range of color options, elegant decorative effects, moisture resistance, corrosion resistance, lightweight, and high strength, aluminum honeycomb panels are used in the production of various types of furniture.

Curtain walls and partitions

Aluminum honeycomb panels, known for their strong water and fire resistance, diverse colors, excellent decorative effects, soundproofing, heat insulation, and fire resistance, are widely used in various curtain wall and partition applications.

Compared to solid aluminum panels, how much weight can be reduced by using aluminum honeycomb panels?

The lightweight advantage of aluminum honeycomb panels comes from their unique structure, where the honeycomb core material in the sandwich structure significantly reduces the overall weight while maintaining relatively high strength.

Generally, using aluminum honeycomb panels instead of solid aluminum panels may result in a weight reduction of approximately 50% to 70%, while still maintaining sufficient structural strength.

This weight reduction is of significant importance in industries such as aerospace and automotive manufacturing.

Aluminum honeycomb panel price

The price of aluminum honeycomb panels varies based on different thicknesses, sizes, and surface coatings.

Chalco, as one of the prominent aluminum honeycomb panel suppliers in China, offers aluminum honeycomb panels in various specifications.

If you have inquiries or questions, you can send us a detailed inquiry with your specific requirements, specifications, quantity, etc. Our customer manager will proactively reach out to you to provide a quotation.