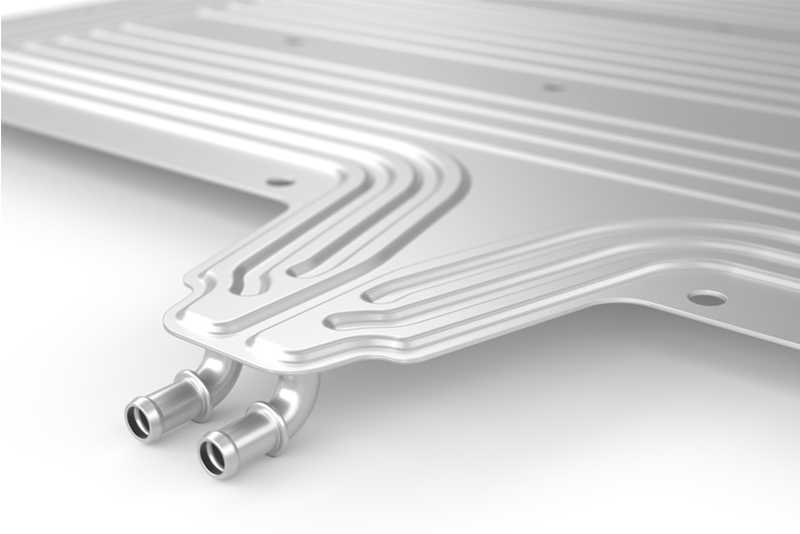

Upgraded Aluminum Brazed Composite Water-Cooled Plate

Updated : Feb. 18, 2024New energy vehicle water cooling plate components are subjected to load-bearing and corrosive environments, necessitating the development of high-strength, corrosion-resistant brazed composite materials to meet various design and application requirements for different water cooling plates.

Structure of aluminum brazing water-cooled plate

The commonly used brazing water-cooled plate structures for batteries mainly consist of two types: water-cooled plate structure and direct cooling plate structure.

Typically, aluminum soldering plate products are formed by brazing two O temper aluminum plates together, with one plate having a stamped flow channel structure. This design facilitates the circulation of antifreeze to cool the battery continuously.

Material strength and corrosion resistance are key considerations for water-cooled plate materials in both structures. Utilizing high-strength composites in the plate design can reduce thickness and costs.

Functions of alloy elements in the composite aluminum brazing water-cooled plate

The changes in alloy composition directly affect the key properties of soldered plates, such as tensile strength, elongation, yield strength, corrosion potential, etc. The table below lists the main elements of aluminum alloy and their functions.

| Element | Influence on the alloy | The content control (percentage) |

|---|---|---|

| Mn | Forming MnAls. strengthening alloy, increasing recrystallization temperature, and affecting grain size. | 1%-6% |

| Fe | Refine grain size to prevent thermal wear on the mold, as excessive grain size can easily form coarse phases. | Mn+Fe<1.85% |

| Si | Improving mechanical properties, reducing the solubility of Mn in Al, and significantly increasing strength. | <0.8% |

| Mg | Significantly enhancing mechanical properties while compromising soldering performance. | <0.3% |

| Cu | Significantly enhancing strength, but excessively high levels can adversely affect processing performance. | <0.8% |

| Ti | Refining grain size | <0.2% |

| Zn | No significant impact on mechanical properties | Unrestricted |

Upgraded core material of the aluminum composite water-cooled plate

In response to increasingly demanding performance requirements, Chalco has conducted research and development on three new core material alloys: 3003-A, 3003-B and 3003-C, which are improved versions of the 3003 aluminum alloy.

The upgraded new materials 3003-A and 3003-B contain higher levels of Cu and Mn elements compared to standard 3003 aluminum alloy. Meanwhile, the core material 3003-C contains even higher levels of Cu, Mn, and Si elements.

| Element | Compositions of different core alloys | |||||

|---|---|---|---|---|---|---|

| 3003 | 3003-A | 3003-B | 3003-C | 4343 | 7072 | |

| Si | ≤0.60 | ≤0.30 | 0.30 | 0.30-0.80 | 6.80-8.20 | Si+Fe<0.70 |

| Fe | ≤0.70 | ≤0.70 | 0.30 | ≤0.30 | 0.20 | |

| Cu | 0.05-2.00 | 0.35-0.50 | 0.65-0.80 | 0.55-0.85 | 0.80 | 0.05 |

| Mn | 1.00-1.50 | 1.00-1.50 | 1.20-1.60 | 1.40-1.60 | 0.05 | 0.05 |

| Mg | 0.05 | 0.05 | 0.05 | 0.05 | 0.05 | 0.05 |

| Ti | 0.05 | 0.05 | 0.10-0.20 | 0.10-0.20 | 0.05 | 0.05 |

| Zn | 0.05 | 0.05 | 0.05 | 0.05 | 0.10 | 0.80-1.30 |

| Al | Remainder | Remainder | Remainder | Remainder | Remainder | Remainder |

Mechanical properties of the upgrade composite brazing sheet after welding

Compared to standard 3003 aluminum water-cooled plates, both 3003-A, 3003-B, and 3003-C core materials exhibit over a 30% increase in strength. Additionally, 3003-C core material achieves even higher strength levels, meeting the requirements for thinning and cost reduction.

Note: in the table, composite material total thickness 1.5mm, composite ratio 10%, alloy condition is O-temper.

| Composite brazing plate | Tensile Strength | Yield Strength | Elongation | ||

|---|---|---|---|---|---|

| Before welding | After welding | Before welding | After welding | Before welding | |

| 3003/4343 | 115-125 | 125 | 48-56 | 45 | 30-38 |

| 3003-A/4343 | 145-165 | 152 | 50-70 | 58 | 20-30 |

| 3003-B/4343 | 150-160 | 160 | 60-70 | 60 | 20-25 |

| 3003-C/4343 | 155-170 | 170 | 65-75 | 55 | 18-25 |

| 7072/3003-A/4343 | 145-165 | 150 | 50-75 | 55 | 20-27 |

Potential performance of the upgrade composite brazing sheet after welding

Corrosion potential is an important indicator for assessing the corrosion resistance of aluminum alloy soldered composite water-cooled plates. The lower the corrosion potential, the stronger the corrosion resistance. Corrosion potential can be controlled by adjusting the content of different alloy components in aluminum alloy.

Increasing the content of Mn, Cu, and other elements will elevate the alloy's potential. On the other hand, increasing the content of Zn will initially lower the alloy's potential before gradually stabilizing. The impact of Si and Mg on alloy potential is relatively minor.

| Composite material | Temper | Core material corrosion potential /V |

|---|---|---|

| 3003/4343 | O temper battery water-cooled plate | -0.720 |

| 3003-A/4343 | O temper battery water-cooled plate | -0.690 |

| 3003-B/4343 | O temper battery water-cooled plate | -0.685 |

| 3003-C/4343 | O temper battery water-cooled plate | -0.695 |

| 4343/3003-A/7072 | O temper battery water-cooled plate | -0.690 |

Choose Chalco aluminum brazing composite water-cooled plates

The water-cooled plate is an indispensable heat exchanger for cooling management in new energy vehicle batteries, playing a crucial role.

- Chalco enhances the mechanical properties of water-cooled plates and reduces corrosion potential by adjusting the aluminum alloy composition, resulting in excellent corrosion resistance performance.

- Production of brazing composite aluminum materials involves using aluminum ingots or large flat ingots. The use of large flat ingots eliminates the need for aluminum ingot casting and can be directly used for hot rolling. The production process mainly includes casting, hot rolling, cold rolling, and finishing.

- The final product takes the form of aluminum composite sheets or coils. The bonding between the matrix and the cladding layer of the composite material is firm, with no cladding layer peeling or partial uncoating phenomenon.

- The surface of the brazing aluminum plate is free from cracks, corrosion, bubbles, through-holes, metallic, and non-metallic inclusions, while soldered composite coils have no joints.