5083 H112 Aluminum Plate

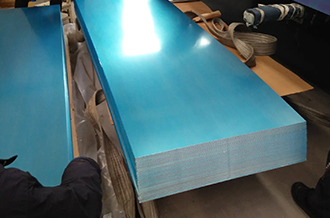

Aluminum 5083 UNS-A95083 aluminum alloy is known for its excellent performance in the most extreme environments and has strong resistance to corrosion from seawater and industrial chemical environments. 5083 aluminum sheet plate has the highest strength among 5000 series non heat treatable alloys, and its strength is high in the tempering state.

The 5083 aluminum plate in H112 temper has excellent corrosion resistance, good formability and welding performance, and can still maintain excellent strength after welding. Widely used in the ocean, transportation, pressure vessels, low-temperature, drilling rigs, natural gas/oil pipelines, weapons, armor plates, etc.; However, it should be noted that it should not be used in high temperature environments above 65 °C.

Chalco 5083 H112 aluminum plate stock size

| Product | Thickness/in | Thickness/mm | Width*Length/mm |

|---|---|---|---|

| 0.157t 5083 H112 aluminum plate | 0.157 | 4 | 1500*3000 |

| 0.197t 5083 H112 aluminum plate | 0.197 | 5 | 1500*3000 |

| 0.236t 5083 H112 aluminum plate | 0.236 | 6 | 1500*3000 |

| 0.315t 5083 H112 aluminum plate | 0.315 | 8 | 1500*3000 |

| 0.394t 5083 H112 aluminum plate | 0.394 | 10 | 1500*3000 |

| 0.472t 5083 H112 aluminum plate | 0.472 | 12 | 1500*3000 |

| 0.551t 5083 H112 aluminum plate | 0.551 | 14 | 1500*3000 |

| 0.591t 5083 H112 aluminum plate | 0.591 | 15 | 1500*3000 |

| 0.630t 5083 H112 aluminum plate | 0.630 | 16 | 1500*3000 |

| 0.630t 5083 H112 aluminum plate | 0.630 | 16 | 2000*4000 |

| 0.709t 5083 H112 aluminum plate | 0.709 | 18 | 1500*3000 |

| 0.787t 5083 H112 aluminum plate | 0.787 | 20 | 1500*3000 |

| 0.866t 5083 H112 aluminum plate | 0.866 | 22 | 1500*3000 |

| 0.984t 5083 H112 aluminum plate | 0.984 | 25 | 1500*3000 |

| 0.984t 5083 H112 aluminum plate | 0.984 | 25 | 2000*4000 |

| 1.102t 5083 H112 aluminum plate | 1.102 | 28 | 1500*3000 |

| 1.181t 5083 H112 aluminum plate | 1.181 | 30 | 1500*3000 |

| 1.260t 5083 H112 aluminum plate | 1.260 | 32 | 1500*3000 |

| 1.378t 5083 H112 aluminum plate | 1.378 | 35 | 1500*3000 |

| 1.575t 5083 H112 aluminum plate | 1.575 | 40 | 1500*3000 |

| 1.772t 5083 H112 aluminum plate | 1.772 | 45 | 1500*3000 |

| 1.969t 5083 H112 aluminum plate | 1.969 | 50 | 2000*4000 |

| 2.165t 5083 H112 aluminum plate | 2.165 | 55 | 1500*3000 |

| 2.362t 5083 H112 aluminum plate | 2.362 | 60 | 1500*3000 |

| 2.362t 5083 H112 aluminum plate | 2.362 | 60 | 2000*4000 |

| 2.559t 5083 H112 aluminum plate | 2.559 | 65 | 1500*3000 |

| 2.756t 5083 H112 aluminum plate | 2.756 | 70 | 1500*3000 |

| 2.756t 5083 H112 aluminum plate | 2.756 | 70 | 2000*4000 |

| 2.953t 5083 H112 aluminum plate | 2.953 | 75 | 1500*3000 |

| 2.953t 5083 H112 aluminum plate | 2.953 | 75 | 2000*4000 |

| 3.150t 5083 H112 aluminum plate | 3.150 | 80 | 1500*3000 |

| 3.347t 5083 H112 aluminum plate | 3.347 | 85 | 1500*3000 |

| 3.543t 5083 H112 aluminum plate | 3.543 | 90 | 1500*3000 |

| 3.543t 5083 H112 aluminum plate | 3.543 | 90 | 2000*4000 |

| 3.740t 5083 H112 aluminum plate | 3.740 | 95 | 1500*3000 |

| 3.937t 5083 H112 aluminum plate | 3.937 | 100 | 1500*3000 |

| 4.331t 5083 H112 aluminum plate | 4.331 | 110 | 2000*4000 |

| 5.512t 5083 H112 aluminum plate | 5.512 | 140 | 2000*4000 |

| 6.299t 5083 H112 aluminum plate | 6.299 | 160 | 2000*4000 |

| 7.087t 5083 H112 aluminum plate | 7.087 | 180 | 2000*4000 |

Mechanical properties of 5083 H112 aluminum plate

| Specification | Specified thickness mm | Tensile strength Rm/MPa | Yield strength Rp0.2/MPa | Elongation % | Hardness HBWa | ||

|---|---|---|---|---|---|---|---|

| Over | Up to | A50mm | A | ||||

| EN 485-2 | 6.00 | 12.50 | 275 | 125 | 12 | - | 75 |

| EN 485-2 | 12.50 | 40.00 | 275 | 125 | - | 10 | 75 |

| EN 485-2 | 40.00 | 80.00 | 270 | 115 | - | 10 | 73 |

| EN 485-2 | 80.00 | 120.00 | 260 | 110 | - | 10 | 73 |

Chemical properties of 5083 H112 aluminum plate

| Element | Composition % (ASTM B209M or B928M) |

|---|---|

| Cu | 0.1 |

| Mg | 4.0-4.9 |

| Mn | 0.40-1.0 |

| Fe | 0.4 |

| Si | 0.4 |

| Zn | 0.25 |

| Ti | 0.15 |

| Cr | 0.05-0.25 |

| Other | 0.15 |

| Al | Remainder |

Thermal properties of 5083 H112 aluminum plate

| Thermal properties | Metric | English | Comments |

|---|---|---|---|

| CTE, linear 68°F | 23.8 µm/m-°C | 13.2 µin/in-°F | AA; Typical; Average over 68-212°F range. |

| CTE, linear 250°C | 26 µm/m-°C | 14.4 µin/in-°F | Average over the range 20-300ºC |

| Specific heat capacity | 0.9 J/g-°C | 0.215 BTU/lb-°F | |

| Thermal conductivity | 117 W/m-K | 812 BTU-in/hr-ft²-°F | |

| Melting point | 591 - 638 °C | 1095 - 1180 °F | AA; Typical range based on typical composition for wrought products 1/4 inch thickness or greater |

| Solidus | 591 °C | 1095 °F | AA; Typical |

| Liquidus | 638 °C | 1180 °F | AA; Typical |

Application of 5083 H112 aluminum plate

The H112 temper is the strongest among all tempers of 5083 aluminum plate, with outstanding strength advantages. 5083-H112 aluminum plate not only has general applications in marine, shipbuilding, transportation and other fields, but also has wide applications in armor plate, tank car plate, mold plate and other fields.

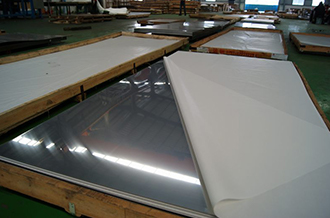

5083 H112 Marine Aluminum Plate

- 5083 H112 marine aluminum plates meet the quality standards of ABS, BV, CCS, DNV, KR, LR, NK, RINA and other ship class aluminum standards, and ensure price competitiveness.

- Moderate strength and good weldability meet the requirements of ship hull for strength, corrosion resistance, and lightweighting, and are commonly used in the manufacturing of ship structures, ship decks, and other parts;

- Excellent corrosion resistance and strength enable it to withstand harsh conditions in marine environments, suitable for underwater hull structures, various marine construction platforms, and LNG storage tanks.

5083 H112 tank truck plate

- Chalco 5083 H112 aluminum plate can reach a maximum width of 2650mm, and can provide surface treatment, precision machining, cutting, stamping, and other overall solutions for customers’ tank trucks project.

- 5083 H112 aluminum plate has a relatively low density and is the preferred choice for tank truck bodies, helping to reduce the overall weight of the vehicle, improve transportation efficiency, and fuel economy.

- The excellent corrosion resistance of aluminum plates makes them widely used in the manufacturing of tank body, and Chalco ultra wide aluminum plates have good formability and welding performance, improving the overall formability of tank bodies.

5083 H112 aluminum armor plate

- Chalco has developed reliable and repeatable cold forming processes in the field of armor plate production, avoiding common faults such as cracks, and has received scientific and engineering validation support.

- It has high strength and lightweight characteristics and is commonly used in the manufacturing of armored vehicle casings, cabin partitions, and other parts, which helps to reduce the weight of the entire vehicle body, improve mobility and fuel efficiency.

- High strength and corrosion resistance make it a common choice for armored vehicle chassis. Sufficient strength and impact resistance to withstand threats from the ground, such as explosives and landmines.

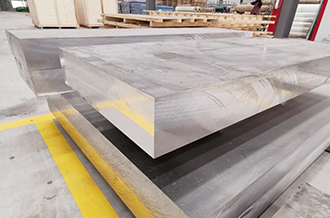

5083 H112 aluminum jig tooling plate

- Chalco 5083 H112 aluminum plate can reach a maximum thickness of 500mm, making it one of the few domestic manufacturers capable of producing ultra thick aluminum plates.

- Aluminum plates have the strength, hardness, wear resistance, and corrosion resistance required for mold plates, fully meeting the requirements of mold manufacturing.

- Widely used in aerospace tools, CNC parts, general engineering, precision engineering, mold and measuring tool manufacturing, tool technology, food industry, medical industry and other mold fields.

Related products

5086 H112 aluminum plate

5052 H112 aluminum plate

5454 H32 aluminum plate

5754 H112 aluminum plate

6061 T6 aluminum plate

6082 T6 aluminum plate