5086 O H111 Aluminum Sheet

Tensile Strength: ≥240 MPa

Yield Strength: ≥100 Mpa

Specification: EN 485-2

Corrosion resistance: High

5086 aluminum exhibits excellent corrosion resistance and moderate strength. Its weldability is an advantage.

It is used in transportation, pressure vessels, low-temperature applications, towers and drilling rigs, natural gas/petroleum pipelines, military equipment, and armored plates.

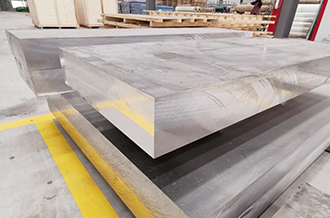

Sizes of 5086 aluminum plates

W*L: 4" x 8", 12" x 12", 18" x 12", 24" x 12", 24" x 24", 36" x 12", 36" x 24", 36" x 36"

| Description | Thinness |

|---|---|

| 5086-O Aluminum Sheet 0.032" | 0.032" |

| 5086-O Aluminum Sheet 0.040" | 0.040" |

| 5086-O Aluminum Sheet 0.050" | 0.050" |

| 5086-O Aluminum Sheet 0.063" | 0.063" |

| 5086-O Aluminum Sheet 0.080" | 0.080" |

| 5086-O Aluminum Sheet 0.090" | 0.090" |

| 5086-O Aluminum Sheet 0.100" | 0.100" |

| 5086-O Aluminum Sheet 0.125" | 0.125" |

| 5086-O Aluminum Sheet 0.160" | 0.160" |

| 5086-O Aluminum Sheet 0.190" | 0.190" |

| 5086-O Aluminum Plate 0.250" | 0.250" |

| 5086-O Aluminum Plate 0.313" | 0.313" |

| 5086-O Aluminum Plate 0.375" | 0.375" |

| 5086-O Aluminum Plate 0.500" | 0.500" |

| 5086-O Aluminum Plate 0.625" | 0.625" |

| 5086-O Aluminum Plate 0.750" | 0.750" |

| 5086-O Aluminum Plate 1.000" | 1.000" |

| 5086-O Aluminum Plate 1.250" | 1.250" |

| 5086-O Aluminum Plate 1.500" | 1.500" |

| 5086-O Aluminum Plate 2.000" | 2.000" |

Material properties of aluminum 5086 O plate sheet

| Specified thickness | Rm (MPa) | Rp0,2 (MPa) | A % | Bending radius | Hardness HBS | ||||

|---|---|---|---|---|---|---|---|---|---|

| More than | Until | mini | maxi | mini | A 50 | A | 180° | 90° | |

| 0,2 | 0,5 | 240 | 310 | 100 | 11 | 1,0 e | 0,5 e | 65 | |

| 0,5 | 1,5 | 240 | 310 | 100 | 12 | 1,0 e | 1,0 e | 65 | |

| 1,5 | 3,0 | 240 | 310 | 100 | 13 | 1,0 e | 1,0 e | 65 | |

| 3,0 | 6,0 | 240 | 310 | 100 | 15 | 1,0 e | 1,5 e | 65 | |

| 6,0 | 12,5 | 240 | 310 | 100 | 17 | 2,5 e | 65 | ||

| 12,5 | 150,0 | 240 | 310 | 100 | 16 | 65 | |||

Chemical composition of 5086 aluminum plates

| Element | Chemical Element |

|---|---|

| Manganese (Mn) | 0.40-1.00 |

| Iron (Fe) | 0.40 max |

| Copper (Cu) | 0.10 max |

| Magnesium (Mg) | 4.00-4.90 |

| Silicon (Si) | 0.0-0.40 |

| Zinc (Zn) | 0.0-0.10 |

| Chromium (Cr) | 0.05-0.25 |

| Titanium (Ti) | 0.15 max |

| Other (Each) | 0.0-0.05 |

| Others (Total) | 0.0-0.15 |

| Aluminium (Al) | Balance |

Processing properties

| Processing Properties | Metric |

|---|---|

| Annealing Temperature | 343 °C |

| Hot-Working Temperature | 316 - 482 °C |

Welding performance

When welding 5083 to itself or another alloy from the same sub-group, the recommended filler metal is 5183. Other suitable fillers are 5356 and 5556.

| Weldability – Gas | Weldability – Arc | Weldability – Resistance | Brazability | Solderability |

|---|---|---|---|---|

| Average | Excellent | Excellent | Poor | Poor |

Anodizing of 5086 aluminum plate

| Bright anodizing | Coloured anodizing | Hard anodizing | Protecting anodizing |

|---|---|---|---|

| Not recommended | Not recommended | Satisfactory | Good |

Corrosion of 5086 plate

| General corrosion index | Corrosion in industrial atmosphere | Corrosion in sea atmosphere | Corrosion in country atmosphere | Corrosion under stress | Exfoliation index | Intercrystalline corrosion | Tapping index |

|---|---|---|---|---|---|---|---|

| Very good | Very good | Very good | Very good | Good | Very good | Good | Very good |

Applications of 5086 O H111 aluminum

- Shipbuilding

- Patrol and workboat hulls

- Rail vehicles

- Dump truck bodies

- Mining skips and cages

- Pressure vessels

- Tank trucks

Advantages of 5086 aluminum plate

- Higher strength compared to 5052 or 5083

- Good corrosion resistance

- Precise dimensions

- Able to withstand high-pressure and high-temperature loads

- Rust-resistant treatment

- Ensures a good stress distribution

- Mechanical properties may vary significantly due to hardening and temperature.

Related products