Ribbed Aluminum Sheet

"Ribbed aluminum plate" typically refers to an aluminum plate with a ribbed structure. This type of aluminum plate has a series of parallel protrusions on its surface, commonly known as ribs. The ribbed structure provides the aluminum plate with greater rigidity and strength while reducing overall weight.

6082 T6 aluminum ribbed plate for marine

The marine aluminum ribbed plate, also called Stiffened plate, is commonly used in ship upper structures. It's formed by extrusion and welding and widely replaces traditional materials due to its sturdy structure, appealing design, and easy installation.

Contact us now

Hot selling specification of marine ribbed aluminum plate

- 4+ ip 50, b=250mm, (6000×2000mm)

- 5+ ip 50, b=300mm, (6000×2100mm)

- 6+ ip 60 , b=250mm, (6000×2000mm)

- 6+ ip 60, b=300mm, (6000×2100mm)

Advantage of Chalco marine ribbed aluminum plate

- High geometric precision;

- Low residual stress;

- Reduced structural welds;

- Improved macroeconomic benefits of shipbuilding;

- Extended ship maintenance service time, increasing total service life.

Welding standard for aluminum extruded ribbed plate

- Welding acceptance standards refer to ISO 25239.

- After welding, surface flatness standard is 5mm/m, with other tolerances according to ISO 13920 BF standard.

- No scratches (0.2mm) on the surface after welding. Minor scratches are acceptable, while severe scratches are treated with a polishing machine.

Aluminum box-type ribbed plate

Box-rib metal panels, featuring repeated box-shaped ribs, serve multiple purposes like roofing, wall panels, and fencing. They also provide bold visual lines due to sharp angles in the repeated corrugations.

Contact us now

Hot selling thickness: available thickness 0.032", 0.040", 0.050

Panel gauge: 20, 22, 24, 26

Stock length: 6'-50', hot selling 8', 10', 12'

Spacing between ribs: 4 inch, 6 inch, 7.2 inch, 8 inch, etc.

Rib height: 1 inch, 1.5 inch, etc.

Hot selling products of Chalco box-type ribbed plate

- 7.2 structural box ribs can be used for roofing, wall panels, or flooring applications.

- Fence panels are durable and stylish, suitable for various uses.

- Valley Box Rib is a wall panel with deep valleys, hiding exposed fasteners.

Advantage of Chalco box-type ribbed plate

- Excellent load and span capabilities;

- Installation on metal wall panels horizontally or vertically;

- Wider panels mean fewer panels to handle and install, saving time and money;

- Available with paint coatings, stucco embossing, anodizing, and other finishing processes;

- Fiberglass panels available to match profiles;

- Third-party testing available to ensure product quality.

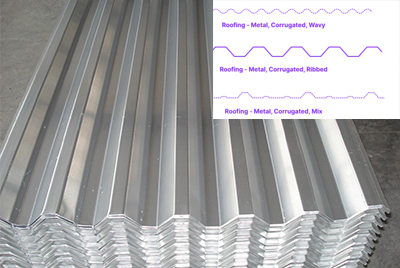

Ribbed corrugated metal roofing

Ribbed corrugated metal roofing features a consistent, regular pattern of raised ribs on the metal sheet. These ribs enhance the structural integrity of the roof, enabling it to withstand heavy loads and resist bending or deformation.

Contact us now

Hot selling width: 36” (91 cm)

Hot selling thickness: 0.02’’(0.5mm)

Length: 8'-20' (2.44-6.1 m)

Panel height: 1.5”-2.25” (3.8-5.7 cm)

Advantage of Chalco aluminum ribbed roofing panel

- Durability, weather resistance, low maintenance requirements.

- Available surface treatments include anodizing, galvanizing, stucco embossing, enhancing the appearance of ribbed panels and improving aluminum plate corrosion resistance.

Ribbed aluminum block for automotive

Ribbed aluminum block is popular in automotive exhaust systems, sealing or terminating both enclosed and formed systems. Crafted from high-quality cast aluminum and polished, these kits offer a stylish, classic design.

Contact us now

Ribbed aluminum plate for sign protection

Ribbed aluminum plates help prevent bending and deformation of signs when mounted on poles. The added strength of the plate prevents damage from overtightening of installation hardware. Hot-selling size: 3*3 inches.

Contact us now

Production capacity of Chalco ribbed aluminum plate

- As an aluminum product supplier, our hot rolling project utilizes the German SMS (1+4) type 4500mm hot continuous rolling production line, with a maximum plate width of 4000mm and strip width of 2650mm, and a minimum thickness of 1.8mm.

- Our cold rolling project utilizes the German SMS six-roll cold rolling mill, 2800mm single-stand CVC cold rolling mill, and 2800mm double-stand CVC cold rolling mill. The aluminum plate can reach a maximum width of 2650mm and thickness of 500mm, with stress relief and non-deformation cutting.

- Chalco has extrusion and welding capabilities to provide finished ribbed aluminum plates. We also offer additional services such as surface treatment, precision machining, cutting, punching, deep drawing, and embossing, providing customers with comprehensive project solutions.