Anodized architectural aluminum plate

Anodized architectural decorative aluminum sheets serve as outstanding new building materials, enhancing corrosion resistance, wear resistance, and aesthetics. Beyond this, they contribute to cost reduction and minimize environmental impact.

Anodized architectural decorative aluminum plate standards

- AMS-QQ-A-250/2

- Mil-A-8625

- EN485-2

- GB/T3880

- ASTM E84

Chalco anodized aluminum panels are typical products in building decoration

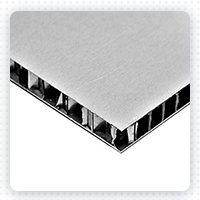

Anodized aluminum honeycomb panel

Anodized aluminum honeycomb panel adopts a 'honeycomb sandwich' structure, which is a composite panel manufactured by combining a surface-coated, weather-resistant, high-strength alloy aluminum sheet as the face and bottom panels with an aluminum honeycomb core through high-temperature and high-pressure bonding.

- Anodized film thickness: 3μm indoors ≥10μm outdoor (can be customized)

- Common plate types: Perforated honeycomb aluminum panel, carved honeycomb aluminum panel, wood-like honeycomb aluminum panel, stone-like honeycomb aluminum panel, curved, and special-shaped honeycomb aluminum panel.

- color: Natural aluminum color, silver, black, white, gold

- Plate thickness: 10mm, 15mm, 20mm, 25mm

- Aluminum plate thickness: 1.0mm, 1.2mm, 1.5mm, 2.0mm

- Board width ≤1600mm

- board length ≤8000mm

- Features: Light weight, high strength, good sound insulation

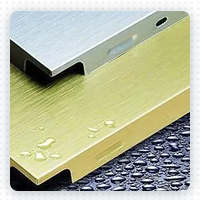

Anodized Aluminum Ceiling Panel

Aluminum gusset plate is a ceiling material commonly used in home decoration, typically used in spaces such as kitchens and bathrooms.

- Anodized film thickness: Indoor 3μm

- colo: Solid color, white, matte white

- thickne: 0.4-1.2 mm

- Common size: 300*300 mm,300*600 mm,450*450mm,600*600 mm,600*1200 mm,1200*2400mm

- Features: Lightweight, stain-resistant, soundproof and heat-insulating

Anodized aluminum perforated panel

Perforated aluminum sheet is widely used in the construction industry for its aesthetic shape, commonly applied in architectural elements such as perforated wall panels, perforated partition boards, and ceiling tiles.

- Anodized film thickness: 3μm indoors ≥10μm outdoor (can be customized)

- Plate type: Flat type, folding type, corrugated type

- perforated graphics: Circle, rhombus, quincunx, gradient graphics, hexagon, cross, triangle

- Aluminum plate thickness: 0.8-6 mm

- Common sizes: 300mm*1200mm 600mm*600mm 600mm*1200mm 1200mm*2400mm 1500mm*3000mm

- Features: Beautiful, lightweight, shockproof, translucent, breathable

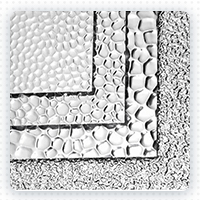

Anodized aluminum pattern plate

The aluminum patterned sheet, also known as aluminum floor plate, aluminum diamond plate, aluminum tread plate, or aluminum checker plate, is a type of metal sheet with raised diamonds or lines on one side, forming a regular pattern, and a featureless reverse side.

- Anodized film thickness: 3μm indoors ≥10μm outdoor (can be customized)

- color: Black, transparent, silver, blue

- Pattern: Five ribs, orange peel, three ribs, lentil shape, compass

- Thickness: 1.2-10 mm

- Common sizes: 1220*2440mm,1000*2000mm,1500*3000mm

- Features: High hardness, corrosion resistance, wear resistance

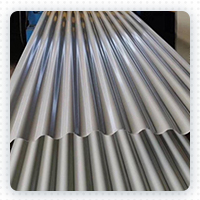

Anodized aluminum corrugated sheet

A corrugated aluminum sheet, typically used in applications such as construction and roofing. This design enhances the strength and rigidity of the aluminum sheet, improving the overall stability of the structure. After anodization, it also significantly increases corrosion resistance, making it particularly suitable for use in humid environments.

- Anodized film thickness: 3μm indoors ≥10μm outdoor (can be customized)

- color: White, silver, metallic transparent color, red, blue

- Aluminum plate thickness: 0.6-3.5 mm

- length: 600-3000 mm

- width: 300-1200 mm

- wave height: 7-18 mm

- wave length: 10-20 mm

- Features: Corrosion-resistant, easy to process, high strength, environmentally friendly

Anodized mirror aluminum plate

Mirror aluminum plate refers to aluminum plates whose surfaces are processed to achieve a mirror effect through methods such as rolling and polishing. Generally, internationally, mirror aluminum plates are produced using the rolling method, resulting in coil or sheet materials.

- Anodized film thickness: 3μm indoors ≥10μm outdoor (can be customized)

- color: Silver, Chinese red, orange, green, champagne, copper, rose gold, light bronze, dark bronze

- Reflectivity: More than 86%

- thickness: 0.1-10 mm

- width: 800-1200 mm

- length: 500-16000 mm

- Features: Corrosion-resistant, scratch-resistant, stain-resistant, smooth and smooth, high gloss

Note: All processes such as laser cutting, punching, bending, mirror polishing, embossing, etc., should be carried out before the anodizing treatment.

All aluminum plates produced by Chalco are equipped with peelable self-adhesive polyethylene protective tape to prevent scratches.

Tolerance range of anodized architectural decorative aluminum plates

| Alloy | Thickness | Tolerance |

|---|---|---|

| 1050, 1060, 1070, 1100, 3003, 3105, 5052, 5005, 5154, 5754, 5083, 5182, 6061, 6063 | 0.1-0.3mm | ±0.02mm |

| 0.31-0.5mm | ±0.03mm | |

| 0.51-0.8mm | ±0.04mm | |

| 0.81-1.2mm | ±0.06mm | |

| >1.2mm | ±0.1mm |

| Alloy | Width | Tolerance |

|---|---|---|

| 1050, 1060, 1070, 1100, 3003, 3105, 5052, 5005, 5154, 5754, 5083, 5182, 6061, 6063 | <1250mm | +3/-0 mm |

| ≥1250mm | +4/-0mm |

Service life of anodized architectural decorative aluminum panels

In order to provide precise data support, Chalco has conducted in-depth scientific research. We conducted tests on anodized aluminum plates for up to 20 years under various outdoor exposure conditions.

In urban environments, coatings with a thickness of 10 to 25µm experience an annual thickness loss between 0.2 to 0.4µm. It's worth noting that coating thickness loss in coastal areas is slightly lower than in urban areas, and in rural environments, there is almost no coating thickness loss.

However, in heavily polluted sites located in the central part of steelmaking areas, the coating thickness loss rate can reach up to 1.2µm per year.

Customers can use this detailed data to have a clear and comprehensive understanding of the film thickness of anodized aluminum plates, enabling them to make better choices and use this high-quality building material more effectively.