6 Common Types of Aluminum Sheet Coatings

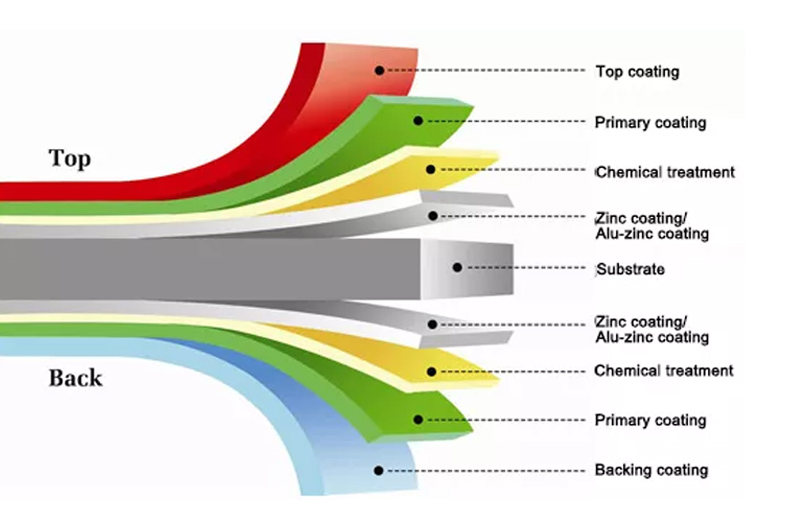

Updated : Jan. 9, 2024In the production process of color-coated aluminum coils, there are a variety of coating materials to choose from. Different coating materials also have corresponding differences in service life and application fields. The following are six common coating materials.

PE (Ordinary polyester coating)

PE coating is an anti-UV coating. Polyester resin uses a high-molecular polymer containing ester bonds in the main chain as a monomer, adding alkyd resin and ultraviolet absorber. It can be divided into matt according to the glossiness. And high-gloss series, the dense molecular structure makes the point surface shiny and smooth.

Chalco uses high-quality aluminum coil sheet substrates and PE materials to produce PE color-coated aluminum plates, which have a corrosion-resistant life of up to 7-8 years and are especially suitable for interior decoration and advertising boards.

HDPE (High weather-resistant polyester coating)

High-performance polyester (HDPE) is also called high-density polyethylene, and its full English name is High Density Polyethene. It has excellent weather resistance, and its hardness and tensile strength are better than PE.

Chalco HDPE color-coated aluminum coils have excellent weather resistance and UV resistance, and the anti-corrosion life can reach 10-15 years. They are ideal materials for blinds, roller shutters, ceilings, roofs, and exterior walls.

PVDF (Fluorocarbon coating)

PVDF fluorocarbon coating is made of fluorocarbon resin with fluorine as the basic monomer, pigments, alcohol ester solvents and additives. After the film is formed by high-temperature barbecue, the molecular structure of the coating is tight and has super weather resistance. Fluorocarbon coatings can be divided into traditional fluorocarbon and nano-fluorocarbon coatings according to the surface film formation structure.

The PVDF color-coated aluminum coils produced by Chalco can last for 25 years without fading, and are particularly suitable for chemical plants, power plants, steel plants, high-speed rail stations, etc. that require high UV resistance and weather resistance..

SMP (Silicon modified polyester)

SMP coating is the abbreviation of Silicone Mobified Polyester coating. Because polyester contains the reactive group -OH/-COOH, it easily reacts with other polymer substances. Modified PE is resistant to sunlight and powdering, and the modified silicone resin has excellent color retention and heat resistance.

SMP has better durability, corrosion resistance can last 10-12 years, and the price is higher than PE coating, but because the material is silicone, its adhesion and formability are not ideal. SMP color-coated aluminum panels are not suitable for applications that require multiple molding processes and are mostly used for roofs and exterior walls of buildings.

EPOXY (Epoxy resin coating)

Epoxy resin is a high molecular polymer, which is the condensation product of epichlorohydrin and bisphenol A or polyol. The epoxy resin coating has excellent alkali resistance, strong metal adhesion, heat resistance and insulation, and good color retention of the paint film.

Chalco EPOXY coated aluminum coils are mainly used for anti-corrosion protection of heat exchange coils, condenser coils and fin materials.

Acrylic resin coating

Acrylic resin is a polymer obtained by polymerization of acrylic monomer. It is characterized by a high degree of light stability, weather resistance and chemical stability.

Acrylic resin coated aluminum coils are mainly used in automobile bodies, electronic and electrical bodies, building exterior walls, etc.