Common Parameters for Perforated Plates

Updated : Jan. 9, 2024Eleven common parameters of perforated plate

1. Hole size or Hole diameter

The hole diameter is often used for round hole perforated plate. In simple terms, it is the diameter size of the hole on the perforated plate.

Chalco offers various diameters for round hole perforated plate and can customize hole diameter according to requirement.

2. Hole center

The hole center refers to the distance between adjacent hole centers on the perforated plate. The measurement of hole center is also commonly used in round hole perforated plates.

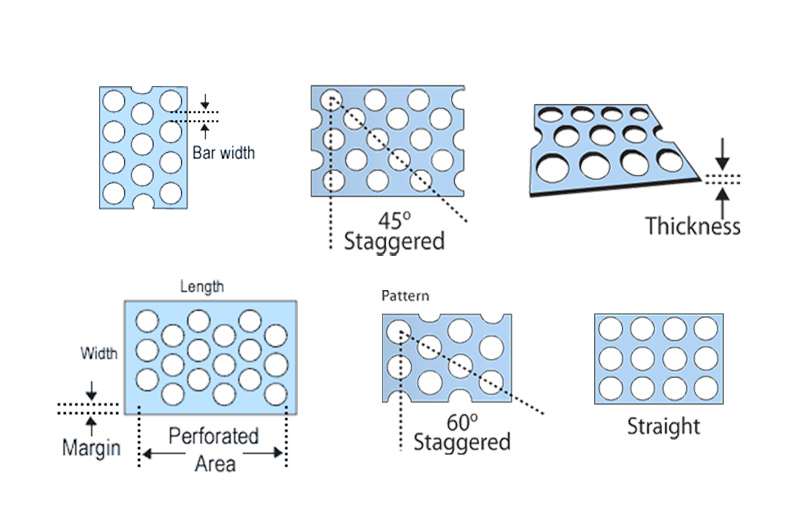

3. Hole pattern

The hole pattern is the arrangement of holes on a board - staggered or straight. In staggered hole patterns, the interlocking direction is usually parallel to the short size of the sheet.

The standard pattern is 60 ° staggered. It is the most robust, versatile, and economical mode of the perforated plate. We also offer straight hole and 45 ° hole patterns.

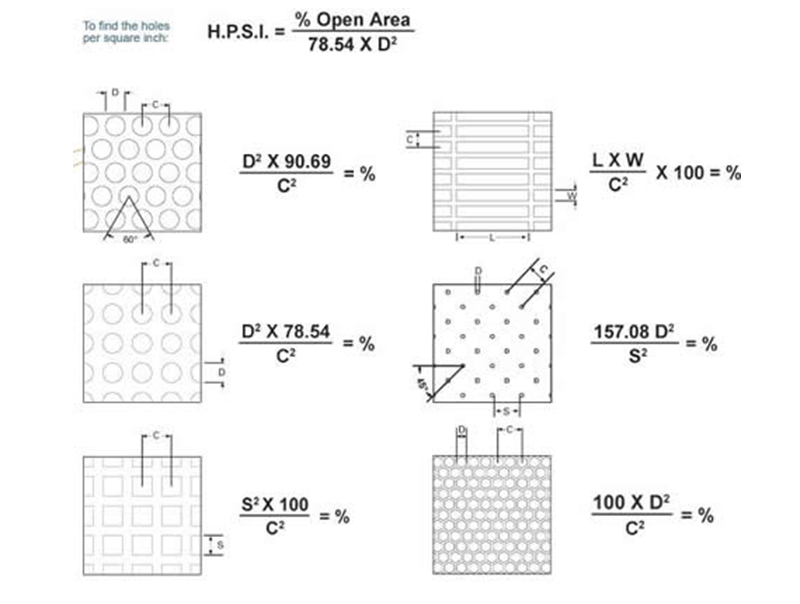

4. Open area or Perforation rate

The percentage of the total surface area occupied by holes on the perforated plate. Perforated plate contains holes and materials. The opening area is the total area of the holes divided by the total area of the plate, and expressed as a percentage.

Simply put, the opening area describes how much of a piece of paper is occupied by holes. If the opening area of the perforated plate is 60%, then 60% of the plate is the hole and 40% is the material.

Note: When selecting perforated plates, only open areas or centers can be specified, but these two parameters cannot be set simultaneously.

5. Bar width

It refers to the width of the metal strip that has not been punched between the holes. It is the size of the material between the outer edge of a hole and the outer edge of the nearest hole. If specifying a bar width, ensure that the bar width meets the minimum bar width criterion.

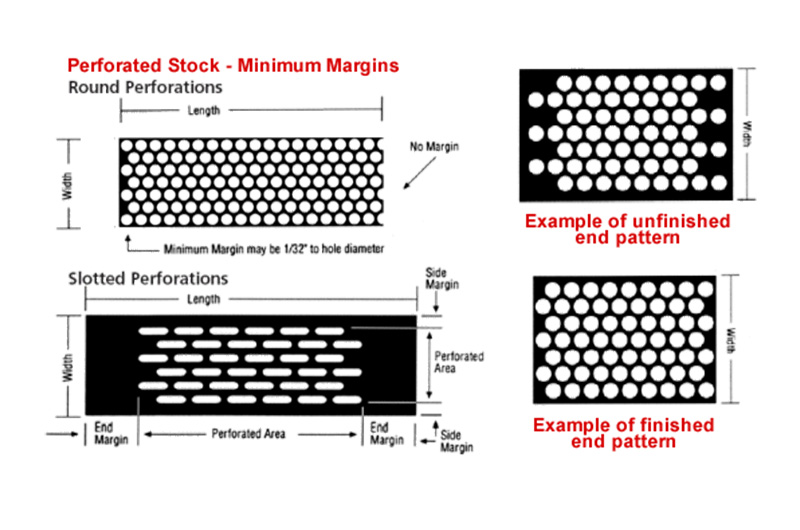

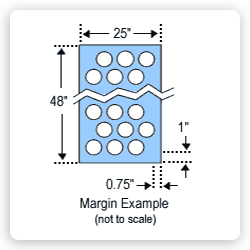

6. Margin

Margins are the blank (unperforated) area along the edges of the sheet. For stock sheets, the standard is minimum margins along the length and no margins along the width.

To specify other than standard margins, use the perforated round hole pattern quote form. Provide the width of each margin on all four sides (measured from the edge of the sheet to the edge of the first hole) and the direction to which the margin is parallel (side or length dimension). Manufacturing considerations may affect margins. If the margins requested are not possible, the quote you receive will specify the new margins.

Below is an example of a margin specification based on the illustration to the left:

Margins:

- 1 inch margins parallel to both 25 inch dimensions

- 0.75 inch margins parallel to both 48 inch dimensions

7. End pattern or End processing

The end pattern is a perforated pattern at the beginning and end of the paper. The ending pattern is either completed or unfinished.

The unfinished end pattern is standard. The completed end pattern requires special tools and is usually more expensive.

8. Thickness or Gauge

The thickness is measured from the top to bottom of the material. Gauge is the most common measurement unit, but thickness can also be measured in inches or mm.

9. Length and Width

The length is the total size of the long side of the plate; The width is the overall measurement value of the short side of the plate.

The perforated plate has standard size and customized size, for specific inventory and pricing, please contact our salesperson for consultation.

10. Quantity

Perforated plates are usually purchased in pieces. When purchasing, you can inform our salesperson of the number of punched plates you need, so that we can check inventory or arrange production.

11. Tolerance

Perforated products have tolerances in terms of quantity, shear force, circular shear force, flatness, thickness, and squareness. If a specific tolerance is not specified, the standard tolerance shall be applied. The tolerance can be specified on the quotation table.

Mechanical equipment for perforated plate

- The production of perforated plates mainly requires plate production equipment and punching processing equipment;

- Chalco has the independent aluminum plate production line, producing high-quality 3003, 5052, 5005, 1060, 1050, and 1100 aluminum plates as raw materials for aluminum alloy punched plates;

- Chalco perforated plate has production and processing equipment such as metal plate uncoiler, leveling machine, slitting machine, shearing machine, punching machine, aluminum coil punching machine, CNC controlled automatic punching plate manufacturing machine, aluminum plate wire mesh punching machine, etc.

- Chalco can provide perforated aluminum plates with round hole, rectangular hole with round edge, square hole, triangular hole, diamond hole, hexagonal hole, cross hole, etc. The maximum working space size of the processing equipment is 1250 * 2500mm, the maximum thickness of the working part is 6mm, the punching accuracy is ± 0.1mm, the number of axes is controlled by four axes (XYTC), and the repeated positioning accuracy is ± 0.1mm.

How to calculate the weight of perforated aluminum plate?

The calculation of the weight per square meter of perforated plates can refer to the following:

ps = absolute (specific) weight (Kg), v/p = open area (%), s = thickness mm, kg = [s*ps*(100-v/p)]/100

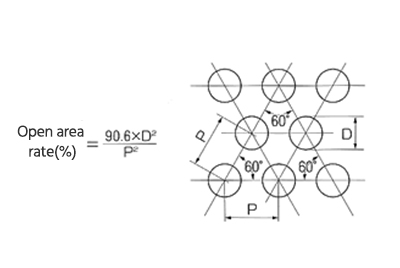

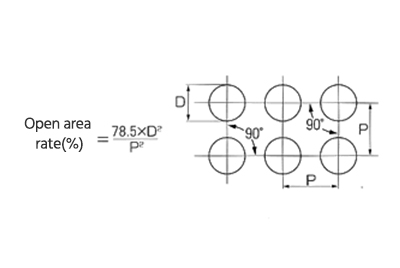

Open area calculation when holes 60° staggered:

V/p = open area (%), D = holes diameter (mm), P = holes pitch (mm), v/p = (D2*90,7)/p2

S = Thickness in mm D = Wire Diameter in mm P = Pitch in mm V = Open Area %

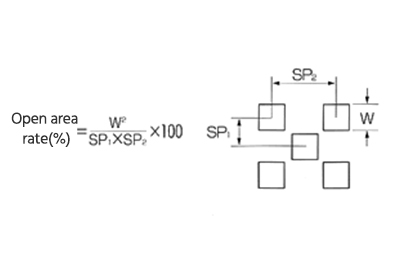

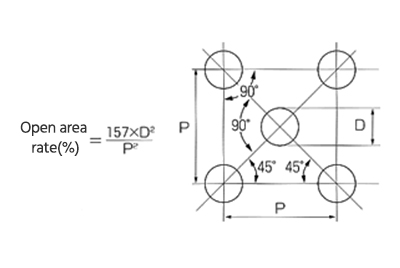

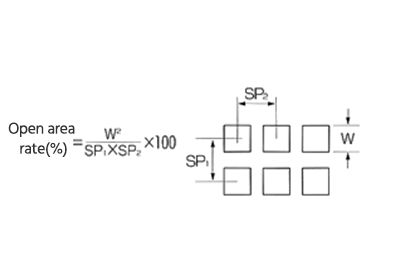

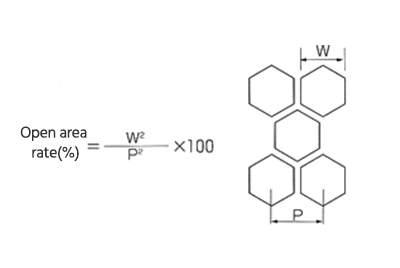

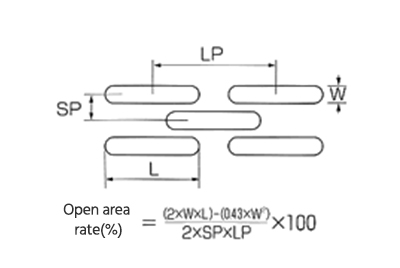

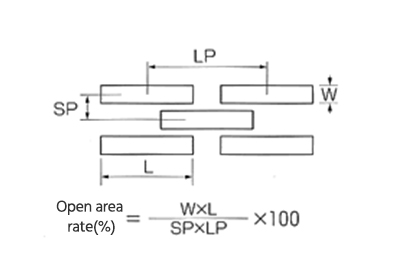

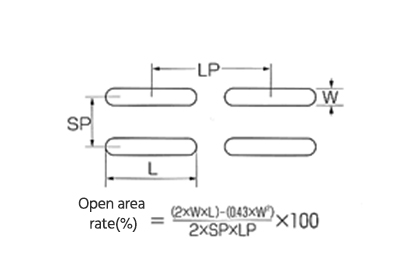

How to calculate the open area rate of the perforated plate?

|

|

|---|---|

|

|

|

|

|

|

|

About Chalco perforated plate

Chalco supplies various aluminum alloy perforated panels, serving industries including architecture, decoration, automotive front grille, safety nets, aviation, and more.

Chalco is committed to producing the highest quality aluminum alloy punched plates on time at competitive prices and continually updating production and testing equipment to ensure the delivery of aluminum alloy punched plates with the highest quality.

If you have various material requirements and technical inquiries about punched plates, you can contact our professional technical personnel for quotations and assistance.