Causes of Vacuum Brazing Leakage in Aluminum Plate-Fin Heat Exchangers

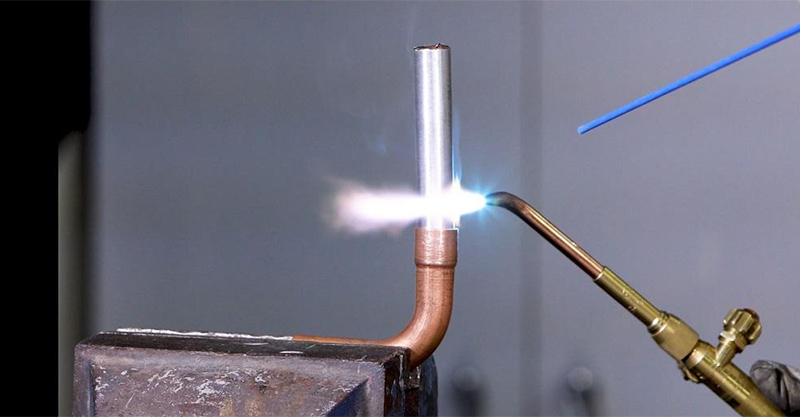

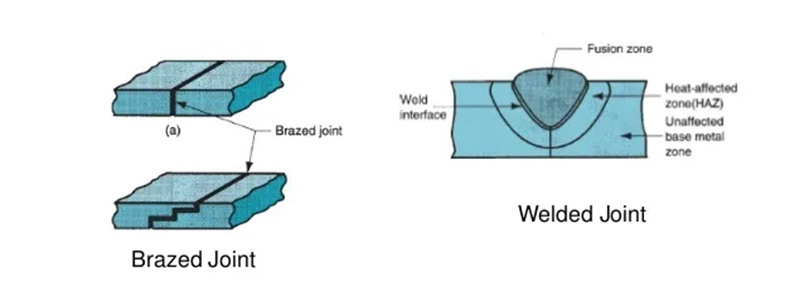

Updated : Feb. 18, 2024Vacuum brazing heats structural components in a vacuum, melting brazing material to bond with solid metal, effectively joining different metals and enabling welding of complex structures. The resulting joints are smooth, dense, with minimal deformation, and exhibit excellent mechanical and corrosion-resistant properties.

Vacuum brazing imposes stringent requirements on the structural design, assembly, composite plate chemical composition, brazing layer thickness, and process of heat exchangers. Failure to meet these requirements may result in quality defects such as bending, incomplete brazing, erosion, and, notably, leakage, which poses a serious issue.

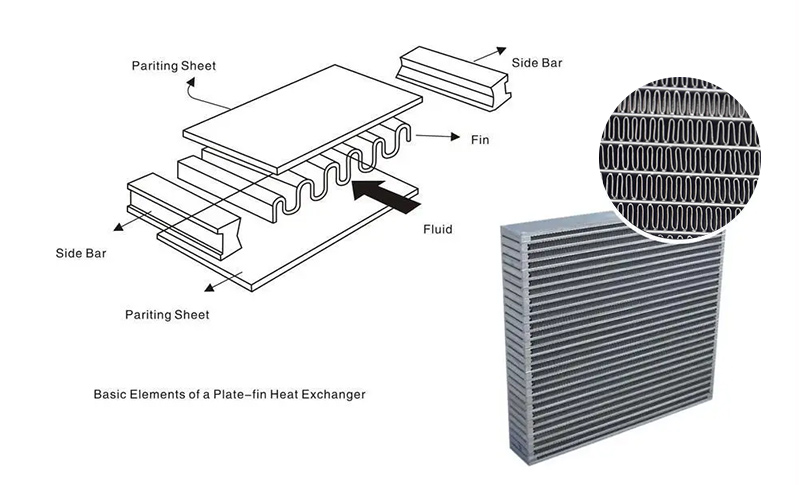

The production process of aluminum alloy plate-fin heat exchangers

Material preparation: shaping and sizing of composite plates, fins, and seals.

Surface treatment: alkali washing → rinsing → acid washing → rinsing → hot water rinsing → drying.

Assembly: mechanical assembly of composite plates, side panels, fins, and seals.

Vacuum brazing: including three stages, namely preheating, energy storage, and brazing in a vacuum furnace. Once the specified temperature is reached, power is turned off and the workpiece is removed from the furnace.

Rectification: mechanical correction of deformation after vacuum brazing of the heat exchanger.

Baffle welding: argon arc welding of baffles at both ends of the heat exchanger, specifically at the large seal positions.

Pressure test: air pressure testing to assess the heat exchanger's pressure-bearing capacity, namely leak testing.

Spraying: cleaning, drying, spraying, and drying of the heat exchanger to enhance its appearance quality.

5 main causes of vacuum brazing leakage

1. Heat exchanger assembly

- Prior to assembly, rigorous surface treatment, including acid-base washing, is essential to remove dirt, oil stains, and oxide film, ensuring effective contact for improved vacuum brazing quality.

- Dimensional tolerances of structural components must be tightly controlled after shaping and sizing to ensure snug fit during assembly, preventing incomplete brazing and disjointed brazed joints.

- To enhance brazing strength, structural component surfaces should be moderately rough, and a 30-degree chamfer should be made on the inside of the seal to reduce brazing material surface tension, increase wettability, and minimize brazing defects.

- When using stainless steel fixtures for heat exchanger clamping, appropriate clamping force should be set per structural design to avoid excessive force causing fin bending or insufficient force leading to fin loosening.

2. Quality indicators of composite plates

The brazing performance of composite plates is related to the fluidity, wettability, filling capacity, and welding strength of the brazing material layer.

- High Si content may cause erosion; the Si range for composite plates used in vacuum brazing is 90% to 105%.

- Mg serves as an activator; when the vacuum degree is high, the standard content is sufficient, but in low vacuum, it should be controlled at the upper limit or higher.

- Composite plates and brazing layers must meet pressure requirements, typically within (10+3)% of the plate thickness, to prevent weak welding and leakage.

- Composite plates act as channel separators and must be defect-free to maintain pressure performance, avoiding issues like pores, slag, poor welds, and physical damage. Excessive brazing material thickness can decrease pressure capacity.

3. Vacuum brazing process

In the vacuum brazing furnace, the workpieces are primarily heated by thermal radiation. It's essential to heat them slowly to maintain consistent internal and external temperatures, ensuring high-quality brazing.

In industrial production, employing a process flow of preheating, energy storage, brazing, and power-off cooling is an efficient method. The brazing temperature and holding time are critical factors affecting the process's efficiency.

4. Vacuum level in vacuum brazing furnace

At high temperatures and low vacuum conditions, residual oxidizing gases react with aluminum to form an oxide film, Al2O3, affecting brazing material flowability and substrate wettability, leading to decreased welding performance.

To minimize Al2O3 formation, improve vacuum levels, control gas content, and ensure multi-zone temperature control with a uniformity of 15°C. The working vacuum level should not exceed 2×10-3 Pa, with a pre-evacuation ultimate vacuum level of 10-4.

5. Environmental conditions during vacuum brazing

Environmental humidity impacts heat exchanger brazing quality. High humidity during assembly can leave moisture on parts. When brazing in a vacuum furnace, moisture evaporation releases gas, affecting internal temperature and vacuum levels, worsening aluminum oxidation, and compromising brazing quality.

Therefore, controlling environmental humidity or implementing alternative methods is necessary before surface treatment, assembly, and brazing.

Conclusion

To reduce or minimize leakage in heat exchangers after vacuum brazing, the following steps should be taken:

- Ensure product quality by sourcing raw materials from reputable, professional manufacturers; consult Chalco for brazing plates.

- Strictly adhere to the process procedures for material preparation, surface treatment, and assembly.

- Optimize and strictly control brazing temperature, holding time, vacuum level, and other process parameters through practical experience; ensure the pre-evacuation ultimate vacuum is at the -4 level.

- Control environmental humidity. Avoid rapid cooling after brazing. Brazing can be done in a nitrogen-filled furnace without vacuum, but the pressure tolerance will be slightly lower.