Architecture Perforated Metal Sheet

Chalco provides customizable perforated aluminum plates, including various sizes, thicknesses, and hole options. Explore our round hole perforated products or inquire for special customization.

Specification of Chalco architecture perforated metal sheet

Material: Aluminum

Alloy: 3003, 5005, 5052, 1100, 1050, 1060 etc.

Size: thickness 0.3–12mm; Width 0.8–1.22 m; Length: 1.2–2.44 m

Hole: Hole diameter 5-100 mm (straight or staggered arranged); Opening area 7% -83%

Specification: ASTM B209

Production equipment: turret punching machines for single perforation, laser cutting, and water jet cutting, etc.

Additional services: customized dimensions, customized hole types, overall finishing services, cutting, welding, and reserved fixing holes, etc.

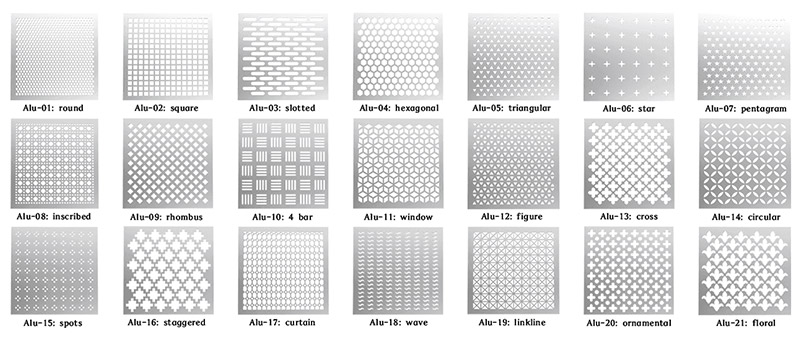

Chalco hot selling architecture perforated metal sheet

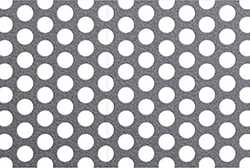

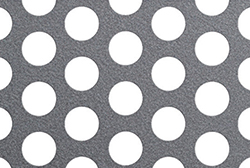

Round hole aluminum perforated plate

Round punched metal products come in various specifications and diameter combinations, making them cost-effective, easy to use, and almost maintenance free. Round perforated metal plates are very suitable for indoor HVAC system components, indoor and outdoor designs, and ceilings.

1/8" d|3/16" stg ctrs|40% open

3/16" d|5/16" stg ctrs|33% open

1/4" d|3/8" stg ctrs|40% open

1/2" d|1" str ctrs|20% open

3/8" d|3/4" stg ctrs|23% open

Customer hole size

Square hole aluminum perforated plate

Square punched holes are aesthetically pleasing, with higher strength to weight ratios and larger openings than other hole types. The square hole pattern has a choice of straight or staggered patterns, giving people a striking appearance and feeling. The square hole pattern is very suitable for many different types of interior and exterior walls.

3/8" Sq| 56% Open|16ga thk

3/8" Sq|56% Open | 20ga thk

1/4" Sq|68% Open|20ga thk

Rectangle Round Slot hole aluminum perforated plate

Rectangular perforated metal plates are commonly used for screens and other filtering applications, providing strength and economy. According to your project requirements, there are various unique sizes and thicknesses of perforated metal plates with rectangular slots to choose from.

1/4" x 1 1/2" Rect Slot | 68% Open | 18ga thk

1/4" x 1 1/2" Rect Slot | 68% Open | 20ga thk

1/8" x 3/4" Round Slot | 41% Open |22 ga

Hexagonal hole aluminum perforated plate

Hexagonal punched mesh is very popular in construction applications. Whether it's internal space separation, partition, or other types of unique applications, hexagonal perforated metal panels are always a popular choice.

1/4" Hex | 9/32 Stag ctrs | -79% Open | 22 ga

1/2" Hex | 9/16 Stag ctrs | 79% Open | 16ga thk

1/2" Hex | 9/16 Stag ctrs | 79% Open | 14ga thk

Customized hole perforated plate

Four elements for purchasing architecture perforated metal sheet

1. Perforation rate is crucial for building efficiency and appearance, controlling light and sound. Chalco offers products with specified rates, ensuring flatness of high perforation rate aluminum plates to meet customer needs.

2. Hole diameter, distance, and arrangement impact visual clarity and image. Chalco punch produces perforated plates up to 1.5m wide, achieving an aperture of up to 80mm (above 80mm, laser equipment is used) for a uniform or gradient visual effect.

3. Thickness is vital for perforated plate, typically 1.0mm to 6.0mm for common plates and 3mm for sound-absorbing panels. Increasing thickness improves strength but must be balanced with perforation rate impact on flatness.

4. Different shapes of perforated plates, such as flat, folded, serrated, wavy, etc., will affect the strength, number of connecting keels, and overall effect of perforated aluminum plates.

Advantages of Chalco architecture perforated metal sheet

- Chalco has aluminum sheet production line and CNC perforation production line, providing more choices in sheet thickness, punching shape, rate and other aspects;

- Provide complete molding, welding, laser cutting, stamping, and assembly services to help ensure the success of your project;

- Comprehensive decoration services, including galvanizing, painting, anodizing, and more, enhance the aesthetics of architectural perforated metal wall panels.

- Assist in green design and assist in developing sustainable products that meet LEED requirements.

- Independent production capacity, customized sizes and patterns, discounted product prices, and free sample provided;

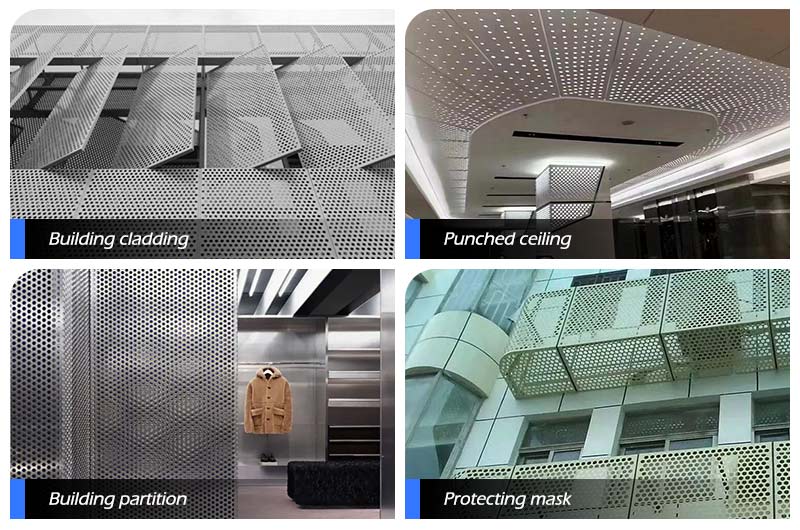

Cooperative industry of Chalco architecture perforated metal sheet

- Building cladding;

- Interior walls and partitions of buildings;

- Ceiling;

- Background wall;

- HAVC system baffle;

- Reinforcement ribs and protective covers for floor applications;

- Installation holes and inspection doors.

FAQ for purchasing Chalco perforated plate

How to choose the proper metal to your perforated plate project?

The best-selling metal perforated plate products in the market include perforated stainless steel plate, perforated galvanized steel plate, perforated brass plate, and perforated aluminum alloy plate. Aluminum alloy plate is occupying most of the metal perforated plate market due to its light weight, good corrosion resistance, good processing performance, and complete recyclability.

How to choose manufacturers and suppliers of perforated aluminum sheets?

Chalco has complete quality certification for high-quality perforated plates, with a complete range of products, large inventory, short delivery time, and can customize plate size, surface, hole diameter, opening rate, and hole pattern according to customer needs. Welcome to inquire and order.

Where can I buy perforated aluminum plates at a discounted price?

The cost of perforated metal plates depends on the type, thickness, and size of the plate, as well as the required design type.

Chalco, with its complete set of perforated aluminum plate production lines, can ensure the production and sales of perforated aluminum plates at the optimal prices.

How to calculate the weight of perforated plate?

Calculation of perforated metal sheet weight per square meter can be done as reference below:

ps = absolute (specific) weight (Kg) , v/p = open area (%) , s = thickness mm , kg = [s*ps*(100-v/p)]/100

Open area calculation when holes 60° staggered:

V/p = open area (%), D = holes diameter (mm), P = holes pitch (mm), v/p = (D2*90,7)/p2

S = Thickness in mm

D = Wire Diameter in mm

P = Pitch in mm

V = Open Area %

[Click to check the detailed information]

How to calculate the opening area of perforated plate?

[Click to check the detailed information]